ATE Pin Electronics have revolutionized the field of automated testing by streamlining the testing process, improving efficiency, and reducing the time-to-market for electronic devices. They enable engineers and manufacturers to ensure the quality, reliability, and performance of their products, leading to increased customer satisfaction and competitive advantage.

What are ATE pin electronics?

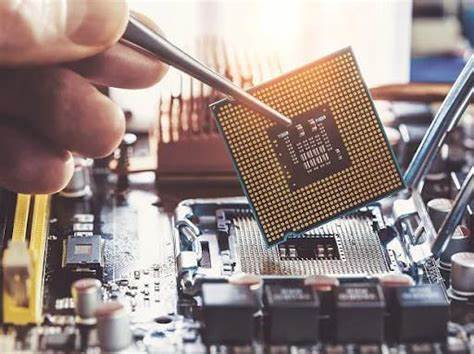

ATE Pin Electronics, also known as Electronics Drivers, are essential components in Automated Test Equipment (ATE) systems. These electronics drivers are responsible for generating and measuring signals that are used to test and validate electronic devices, such as integrated circuits (ICs), printed circuit boards (PCBs), and other electronic components.

ATE Pin Electronics play a critical role in the test automation process by providing precise control over the electrical signals applied to the device under test (DUT) and accurately measuring the responses. These drivers are designed to simulate real-world operating conditions, allowing engineers to evaluate the performance, functionality, and reliability of electronic devices before they are released to the market.

Working of an ATE pin electronics system

The primary function of ATE Pin Electronics is to generate electrical stimuli, including digital signals, analog signals, and power supplies, to simulate various input scenarios that the electronic device may encounter during its operation. These stimuli can include voltage levels, clock signals, data patterns, and voltage transitions.

ATE Pin Electronics also enables the measurement of the device’s responses to these stimuli. They can capture and analyze the output signals produced by the DUT, such as analog voltages, digital states, and response times. These measurements are crucial for assessing the device’s functionality, performance, and compliance with specifications. Here is a step-by-step process of how an ATE pin electronic system functions

- ATE Pin Electronics generates precise electrical signals to stimulate the device under test (DUT).

- They measure the DUT’s responses to evaluate performance and functionality.

- Timing control allows the simulation of different operational scenarios and the assessment of response time.

- Fault detection and diagnosis features identify and troubleshoot issues during testing.

- Real-time monitoring tracks critical parameters for prompt anomaly detection.

- Integration with test fixtures and control through software streamlines the testing process.

- ATE Pin Electronics are compatible with various electronic devices and scalable for future needs.

Advantages of an ATE Pin electronics system

- Realistic Simulation:

ATE Pin Electronics simulates real-world operating conditions, allowing engineers to test devices under different scenarios. This realistic simulation helps uncover potential issues and ensure the reliability and performance of electronic devices in various environments.

- Fault Detection and Diagnosis:

These electronic driver systems incorporate fault detection and diagnosis features, enabling prompt identification and troubleshooting of issues during testing. This capability helps streamline the debugging process and reduces the time required for problem resolution.

- Data Analysis and Insights:

Pin Electronics capture and analyze data during testing, providing valuable insights into the performance of electronic devices. These insights can be utilized to optimize designs, improve manufacturing processes, and enhance overall product quality.

- Scalability and Future-Proofing:

These systems are often scalable, allowing for expansion and reconfiguration as testing needs evolve. This scalability ensures that the system can adapt to new technologies and accommodate future testing requirements.

- Quality Assurance:

By thoroughly testing electronic devices using ATE Pin Electronics, manufacturers can ensure the quality and reliability of their products. This helps in meeting industry standards, regulatory compliance, and customer expectations, leading to increased customer satisfaction.

- Cost Savings:

ATE Pin Electronics systems help identify defects and issues early in the manufacturing process, reducing the costs associated with product failures, rework, and warranty claims. This cost-saving benefit contributes to improved profitability for manufacturers.

- Versatility and Compatibility:

An electronic driver is designed to be compatible with a wide range of electronic devices, accommodating various pin counts, types, and signal requirements. This versatility enables efficient testing across different products and technologies.

ATE Pin Electronics have revolutionized the world of automated testing, providing engineers and manufacturers with the tools they need to ensure the quality, reliability, and performance of electronic devices. From consumer electronics to automotive and aerospace industries, the applications of ATE Pin Electronics are diverse and far-reaching. As technology continues to advance, we can expect to see further innovations in this field, making testing faster, more accurate, and more efficient than ever before.

John Miller has been writing about science, gaming, and tech culture for over a decade. He’s a top-rated reviewer with extensive experience helping people find the best deals on tech and more.